folkprophet wrote:For the end knot, I have a few questions (not quite there yet, but am thinking about it).

1. How big should the final knot be (diameter) for an Indy Whip?

2. If the knot is that ^ big, what should the width of the strands be to do 3 passes. And how long will the strand for it need to be.

3. Is there some sort of equation for figuring strand width based on the diameter of the ball prior to tying the knot?

4. Same questions for the other knot...which I can't remember what it's called...but at the other end of the handle. It's smaller, but only has 2 passes, right? So the same strand width? And how long will I need the strand for that?

Thanks again all!

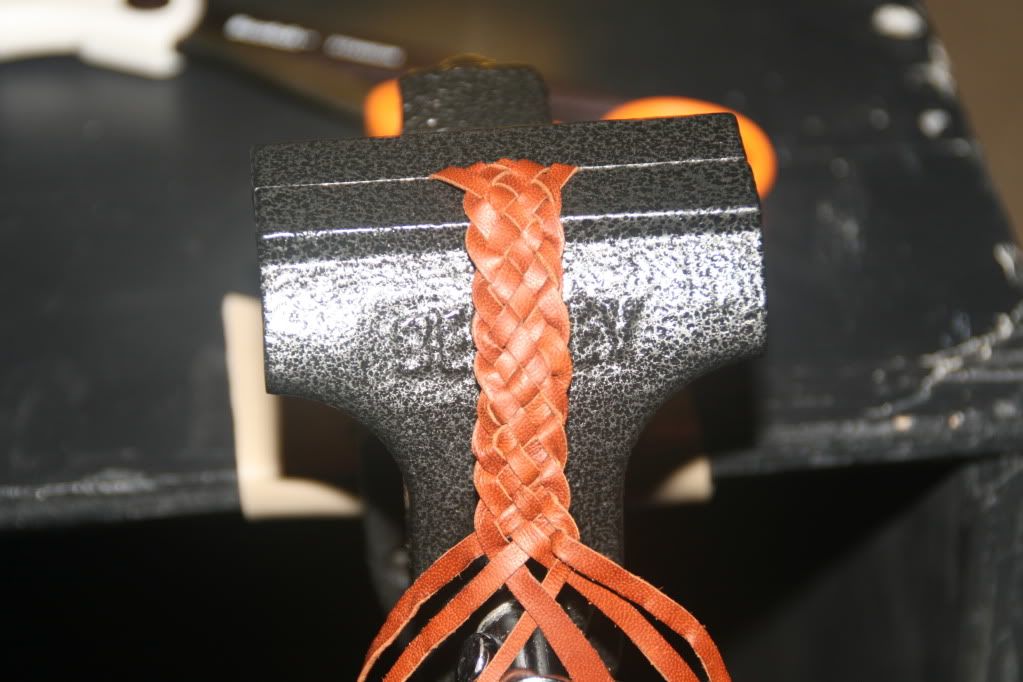

1: Doesn't really matter. It's pretty much up to your personal preference. Some people like a small heel knot, others like myself like a large one to be able to grip really well. Personally I like the widest point on it to be at least 1.6 inches ( speaking inches because that's how the raiders whip heel knot was measured ) but more like 1.8 is most comfortable.

2: Can't say for sure. Depends on a lot of things. First of all, the knot has 4 bights and 3 passes. Second, it depends on how much of the knot you want to cover. You can have the entire heel covered, or have a lot or a little leather showing in the heel. You'll have to look at a lot of other knots, gauge how large they are and figure it out from there.

3: Probably figured it out from 2, didn't you? None that I have found. I've heard a few different ones but none of them worked because there are SO many variables with the knots.

4: Transition knot / ring knot . On the indy whips they again have 4 bights, but 2 passes , you are correct. No, not the same strand width. Typically for a 5x4 2 pass transition knot, the lace will be anywhere from 4-6 mm wide. It depends on the thickness of the whip.

5: ( I added one

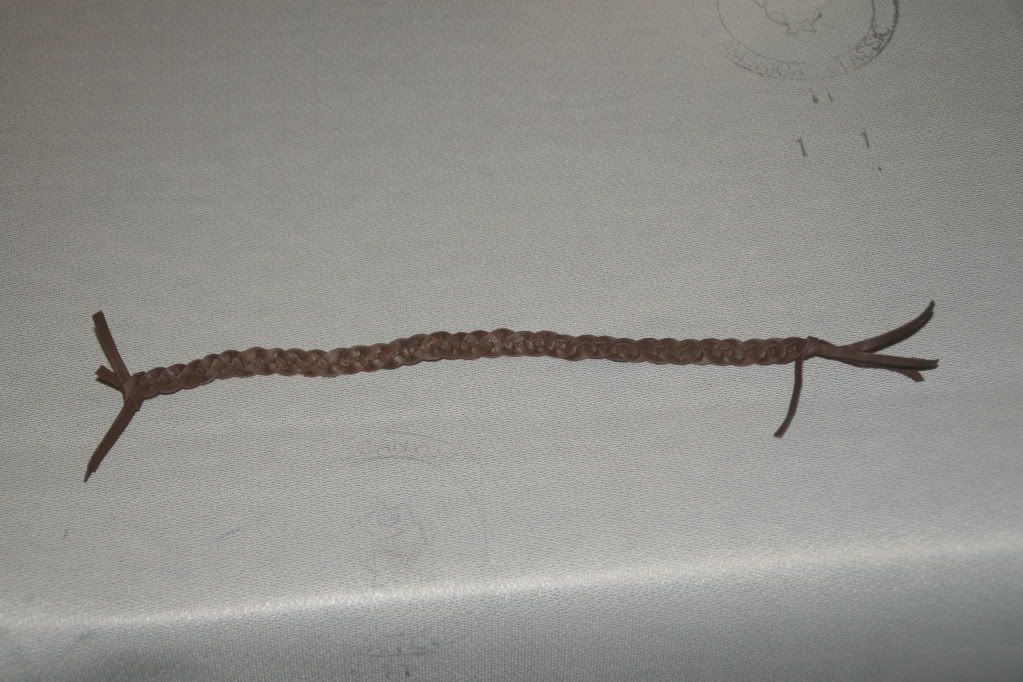

) Lace length. Again it depends on a few things, but typically I cut my heel knot lace on a 5x4 3 pass heel knot 6-8 ft. long. I have plenty left over, but that's ok, I use it for whip handle keychain knots ( which I of course have to size down ). You could use it for something like a wrist loop, or if you have enough left over you can size it down for the transition knot ( that's what I used to do ).

For a 5x4 2 pass transition knot, I usually cut my lace 4-5 ft. long. I then have enough left over to do a whip handle keychain transition knot, and then have some left over. So I would suggest cutting your lace 4 ft. long and seeing how much you have leftover. That's enough so that you can ensure you have enough, but not have too much waste if there's bunches left over.

Cutting them all at once also helps with consistency ( speaking of plaited layers now ). You don't get to cut the whole strand in one go, but since they are at the same time you're able to keep track of things easier. There's nothing wrong with one at a time, it can work, I'm just telling you what helps me best.