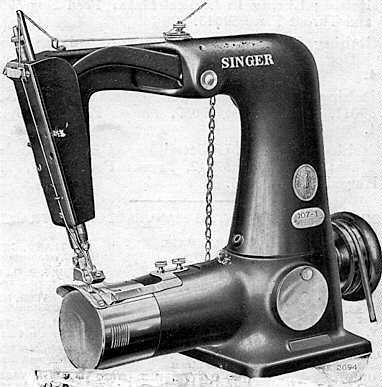

The problem came in when I made my assertion about sewing machines, since I am familiar with machines that use, by default, a dual-thread "lock-stitch." I was not aware that any sewing machines currently in use used the single-thread chain stitch anymore. Tailoring sewing machines haven't for the better part of a century. The single-thread chain stitch is very, very old and, as stated, not very strong. Here is a quotation from a Wikipedia article on chain stitching that explains this: "Chain stitch was the stitch used by early sewing machines; however, as it is easily unraveled from fabric, this was soon replaced with the more secure lock-stitch." http://en.wikipedia.org/wiki/Chain_stitch. I am not sure why these specialized hatting sewing machines continued to use that stitch, when general sewing machines had long abandoned it.

Here is an article that contains an animated illustration that shows how a typical sewing machine's lock-stitch is formed http://en.wikipedia.org/wiki/Lockstitch. Lock-stitches are pretty strong, and though any stitch can be unraveled if enough threads are broken in it (unless you tie off a knot in the thread after every stitch), these will be very strong and would not come loose unless you deliberately cut several of the stitches with scissors or something and pulled very hard on the material sewed together. You can also do all kinds of other stitches with them that would secure it even further, if you really felt it was necessary. They also would make very tiny holes, as you can use a much wider selection of needles on these machines, than on the Singer 107 and probably similar industrial hatter machines.

So I hope this info is helpful to the curious, and maybe will help clear up some misunderstanding that resulted from the recent discussion on sweatband sewing with machines versus hand-sewn.

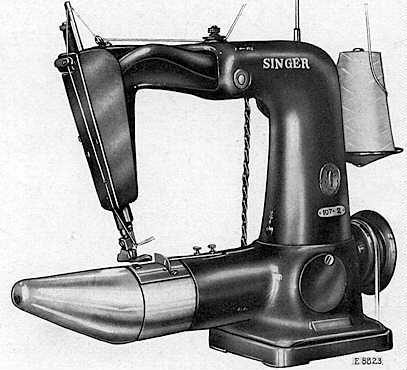

For those who may be interested, here is the user manual for the Singer 107 sweat-sewing machines - http://parts.singerco.com/IPinstManuals/107_1_2.pdf.