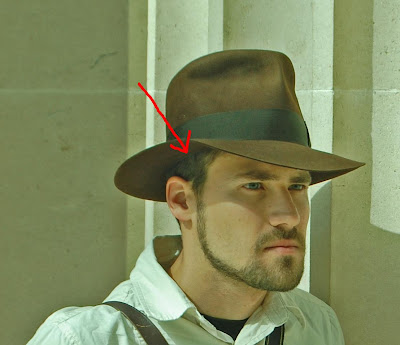

One of the first things I look at on a hat is how well the sweatband is installed. An easy way to tell is by doing what I call the snap test, where I pull the reed away from the hat and see if it “snaps” back into place. If it’s been sewed in nice and tight, it should make an audible pop and always lay flush up against the felt. I like to see the sweatband sunk deep down into the crown. I should never be able to see a gap between the edge of the sweatband and the felt where the arrow is in this picture. Note that there is absolutely no gap in the picture here of my Penman

Another thing that really matters to me is the quality of the pouncing. You might not be aware that there are actually variations in pouncing techniques which lead to slightly different finishes. Most obvious is the smoothness of the finished hat. Generally custom hats have a much smoother finish than factory hats – a direct result of the amount of time spent pouncing. Some factory hats may not even get any pouncing treatment at all. Getting more specific though, you could also describe the pounce job by how long the surface hairs are, or by how (or even if) they lay down. Does the felt feel smooth rubbed in both directions, or is it more like velvet if you rub against the grain? This is one area where different hatters can really show off and stand out from one another. Keep in mind though there’s no one way that’s better than the rest. As with most things it comes down to personal preference.

I believe ribbon work on a hat can be very telling of the quality of the hat overall. The ribbon is kind of like the finishing touch of a hat, and if care has been taken on the installation of the ribbon, chances are for likewise on the rest of the hat. First I look at the ribbon in general and make sure that it's free of wrinkles and creases that aren't supposed to be there. This is really basic stuff and if the ribbon is wrinkled I lose interest quickly. It’s on the ribbon where the most visible of stitches on the hat lie. I generally say that the less obvious the stitches are on the ribbon the better. Some hatters do such a great job at hiding stitches that they practically become invisible. This is great for the tack down stitches especially because it ensures an even and smooth ribbon all around the hat. One exception might be on a raiders hat, where as we know from the screenused pictures, the stitches on the hero hat were very obvious. If you’re going for screen accuracy, you may want the ribbon stitches placed very noticeably in the middle of the ribbon. A ribbon should also fit extremely tight all around the crown. If you run your finger along the upper edge of the ribbon, you should not be able to pick up any “slack” in the ribbon as your finger moves around. A well made bow should be able to hide it’s own construction. I don’t like having any end of the ribbon visible behind the bow. This area should be clean like the red arrows in the picture. I also look at where the bottom of the knot

of the bow touches the hat and make sure none of the sweatband stitching is showing through under the knot (blue area in photo).

I also want to mention the quality of the ribbon itself. Ribbon quality varies widely. Hat ribbon, in my opinion should be grosgrain, meaning the edges of the ribbon are finished. This just makes everything look a lot nicer than seeing an unfinished ribbon. Also notice how wide the folds in the ribbon material are. The narrower they are, the higher the thread count and the better the ribbon. Vintage ribbon usually trumps here.

So those are just a few of the bigger things I look for in hats. What else do you find important?

Regards,

Brian